Reducing Logistics Costs: Step by Step Guide | OPLOG

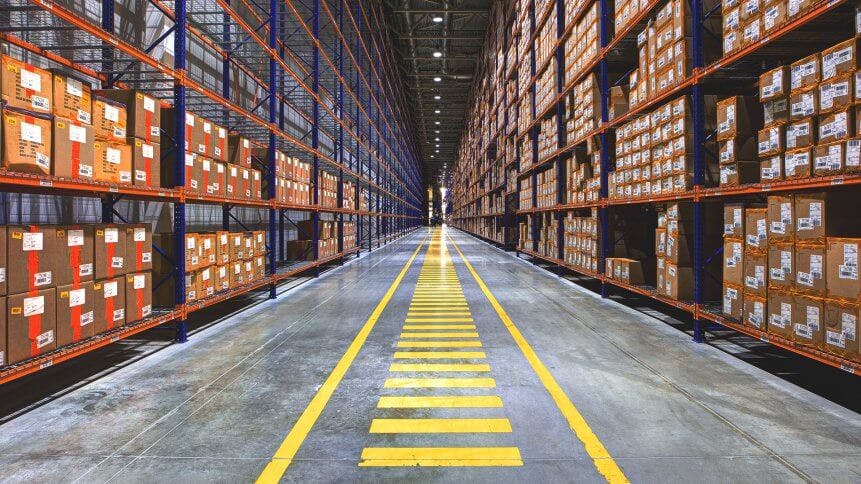

Imagine a field that has an impact on the GDP of the countries by %13. No, I am not talking about agriculture or industries; I am talking about logistics. When not managed carefully, the cost of logistics can hurt your business to the degree you don’t want to experience. However, optimizing warehouse logistics management can impact both your customer satisfaction and savings to a significant degree. So, let’s look at how you can reduce your logistics costs at your warehouse.

What factors primarily affect logistics costs?

Yes, managing a warehouse is a complicated process, and some factors affect logistics costs without you not noticing them. Here is a list of items you might be looking over:

Internal Transportation: If you move your inventory within the warehouse often, this pointless movement may increase your costs. This problem doesn’t appear often but if you are facing a situation where the inventory moves around frequently, this may indicate that you did not plan your warehouse efficient enough for stock increases or campaign seasons.

Overproduction: Not balancing your inventory in accordance with your supply and demand requirements can cause a huge mess in your warehouse.

Under-administration: The absence of consistent operating procedures can cause using the wrong equipment for necessary tasks or employees choosing their tasks as they see fit (and not according to your priorities. The delays resulting from this can lead to lower customer satisfaction rates and sales.

Waiting: If the warehouse works in an un-synchronized way, it can result in waiting for the products to be shipped, which in turn means unhappy customers or even lost sales.

Flaws: The lack of decent quality control and quality assurance measures can result in shipping defective products, which will increase returns and costs.

Fuel Costs: The cost of fuel can directly increase your logistics expenses, but unfortunately, we cannot control this item. However, the number of options is rapidly growing as we are on the verge of adopting electric vehicles globally.

Regulations regarding international trade: The document processing and compliance checks will affect the costs you pay for logistics. The main reason this happens is the time spent on the documentation process, which can cause delays in shipment, doubling the waiting duration. Ultimately, unhappy customers will no longer come back to shop for your products.

How can you reduce the costs of logistics in warehouses?

To help alleviate the impacts listed above, we have prepared a list of options that you can use to reduce the logistics costs in your warehouses.

Remove open spaces in an orderly manner

Yes, this is quite a cliché, to be frank, but do you actually practice it? If your answer is no, you may gain some advantage doing it. One advantage it brings is that it increases the eagerness among warehouse workers toward organized operations. Being organized can help reduce the damage by eliminating transit movement. Also, you can improve the available floor space to enhance storage density.

Consolidated shipment

Most firms choose the less than container load (LCL) option as it is more profitable and safer than full container loads (FCL). You will be transporting goods in small freight when you consolidate your shipments. In other words, you combine several small shipments that have the same destination to make a consolidated shipment. Also, the improvements in logistics providers may allow you to make cost-effective shipments as they partner up with other importers.

Understand your costs

This recommendation sounds very basic but is extremely important for your business. We have listed some of the alternatives that may have been causing an increase in your costs. However, the cost of labor always runs the show. So, automating processes that require repetitive tasks such as carousel picking or product slotting will diminish your expenses. Besides, SKU intensity is also crucial if you have a range of colors and sizes in different products. Basically, you can easily detect the sizes and colors that are not selling and avoid overstocking.

Use an integrated platform

Using a single platform to manage your logistics operations is key for cost savings. Ultimately, the more platforms you add to your operationn, the less efficiency you will have, as the problems in one of them will affect the maintenance of another. Also, as mentioned earlier, it can lead to overproduction, thereby duplicating work which causes disruption in efficiency.

Why not outsource your operation?

The outsourcing logistics market is predicted to reach 1,306.56 billion USD in 2027. This clearly states the tendency for outsourcing logistics operations globally but let us share more about its advantages. First, it increases your customer service by providing fast and affordable shipping of your products while collecting data on your supply chain process and using its technology to review the delivery times, exceptions, and more.

Next, working with a 4pl company does not mean you lose the exclusivity of your business. Your business is not the same as others, and an experienced 4pl company can provide you with the necessary personalization needed. For instance, you can customize freight invoice auditing carrier, vendor management, and freight claims without trouble. And you will get reports regularly about the performance of your logistics operations.

If you are interested in lowering logistics costs, you can book a meeting with one of our fulfillment experts and start gaining momentum on logistics operations. You can also see how we helped a 20000+ stocked company to scale since transferring its business to OPLOG.