In today's fast-paced e-commerce world, efficient warehouse management isn't just a luxury—it's a necessity. According to an Emerald Insight study, the number of UK retailers that have not invested in warehouse automation in any way decreased from 32% to 8% in 2023.

A Warehouse Management System (WMS) serves as the backbone of modern logistics operations, transforming how businesses handle inventory, fulfill orders, and deliver customer satisfaction. Let's dive into everything you need to know about WMS and how it can revolutionize your warehouse operations.

Store More, Stress Less: Understanding WMS Basics

A Warehouse Management System (WMS) is sophisticated software that orchestrates the entire symphony of warehouse operations—from inventory management to order fulfillment. Think of it as your warehouse's brain, coordinating everything from the moment goods arrive until they're shipped to your customers. With advanced solutions like OPLOG's smart WMS, businesses can achieve foolproof stock management while maintaining 99.9% order accuracy.

Getting Down to Business: How Does a WMS Work?

Modern WMS solutions do more than just track inventory—they're the command center of your warehouse operations. By integrating seamlessly with e-commerce platforms and ERP systems, a WMS coordinates:

- Real-time inventory tracking and updates

- Efficient order processing and fulfillment

- Optimized storage organization

- Automated picking and packing processes

- Comprehensive shipping management

Consider this order status screen of OPLOG ONE, demonstrating live order tracking from creation to delivery and exemplifying how a WMS can increase the visibility of your operations:

The Perfect Match: Integration with Other Systems

One of the greatest strengths of a modern WMS is its ability to play well with others. Like OPLOG's proprietary system, leading WMS solutions offer seamless integration with:

- E-commerce platforms

- Enterprise Resource Planning (ERP) systems

- Transportation Management Systems (TMS)

- Customer Relationship Management (CRM) tools

- Accounting software

Warehouse Wins: Benefits of Implementing a WMS

Having a system for warehouse management will ease your general workflow. You will notice differences like accurate inventory, adept operations, and enhanced customer service. It's an all-around business boost – from the ground floor workers to client-facing operations.

Precision Perfect: Improved Inventory Accuracy

Say goodbye to the "where-did-I-put-that" syndrome. A WMS provides real-time tracking and automated data entry, reducing errors and keeping your stock counts accurate. OPLOG's WMS, for instance, maintains 100% foolproof stock management through its innovative tracking system.

Speed, Speed: Enhanced Operational Efficiency

Modern WMS solutions include picking robots that eliminate the need to walk around the warehouse, replacing humans at several steps of the fulfillment process. For instance, powered by cutting-edge technology, OPLOG's picking robot TARQAN can:

- Optimize picking routes for maximum efficiency

- Reduce warehouse travel time by up to 400%

- Accelerate order fulfillment

- Streamline receiving and put-away processes

Customer Satisfaction Champions: Better Service

With precise order fulfillment and reliable delivery times, your customers will thank you. Real-time tracking, accurate stock counts, and predictive analytics help maintain high satisfaction levels and encourage repeat business.

Take a look at this OPLOG ONE screen, showcasing automated return analysis:

It is an example to help you better understand how a real-time tracking system, the first-born of a WMS, can help you reach daily information regarding your operations and offer insightful data.

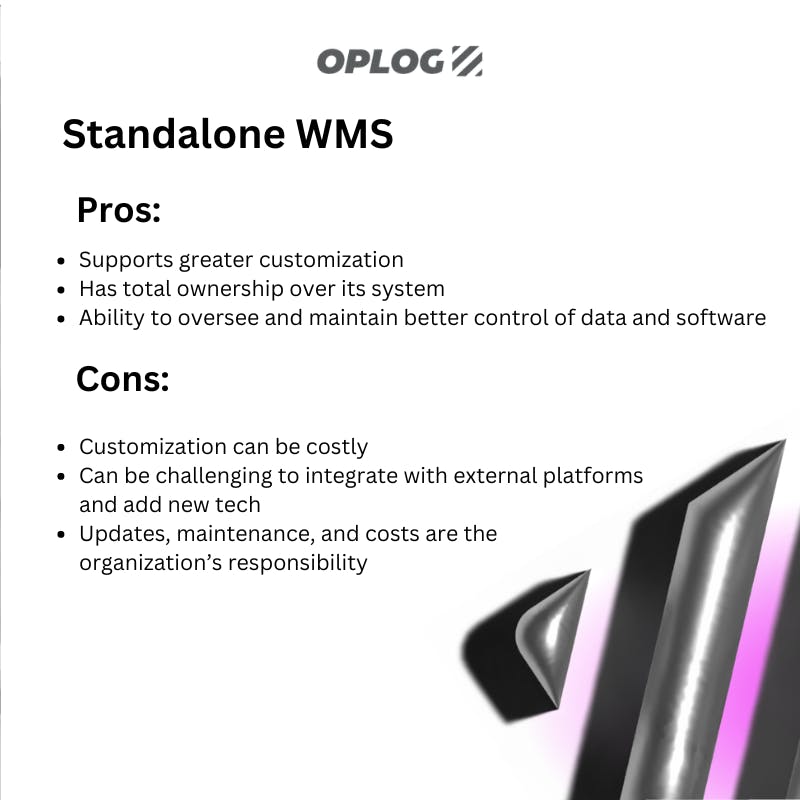

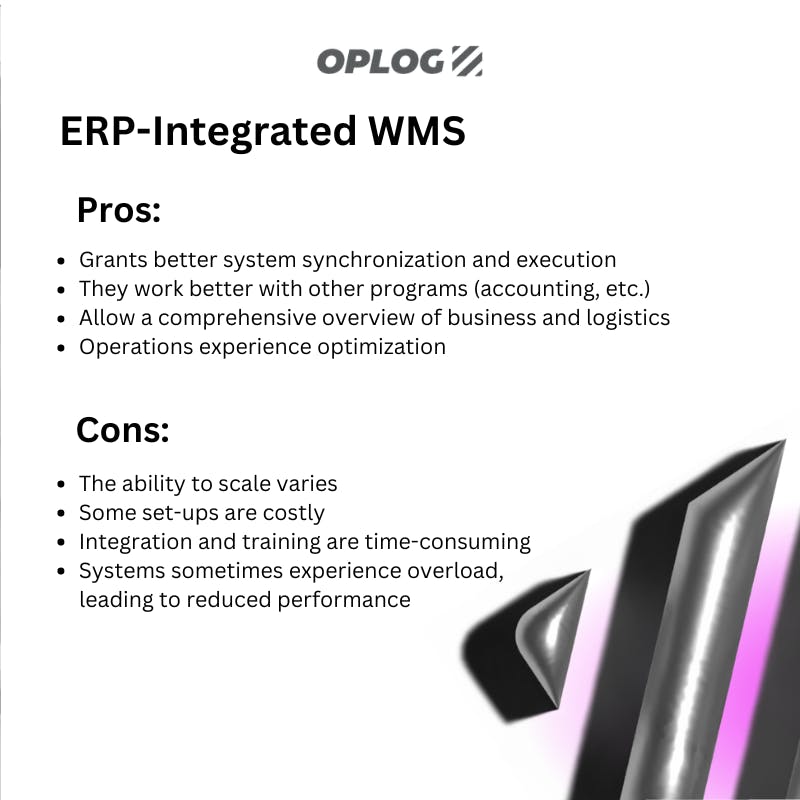

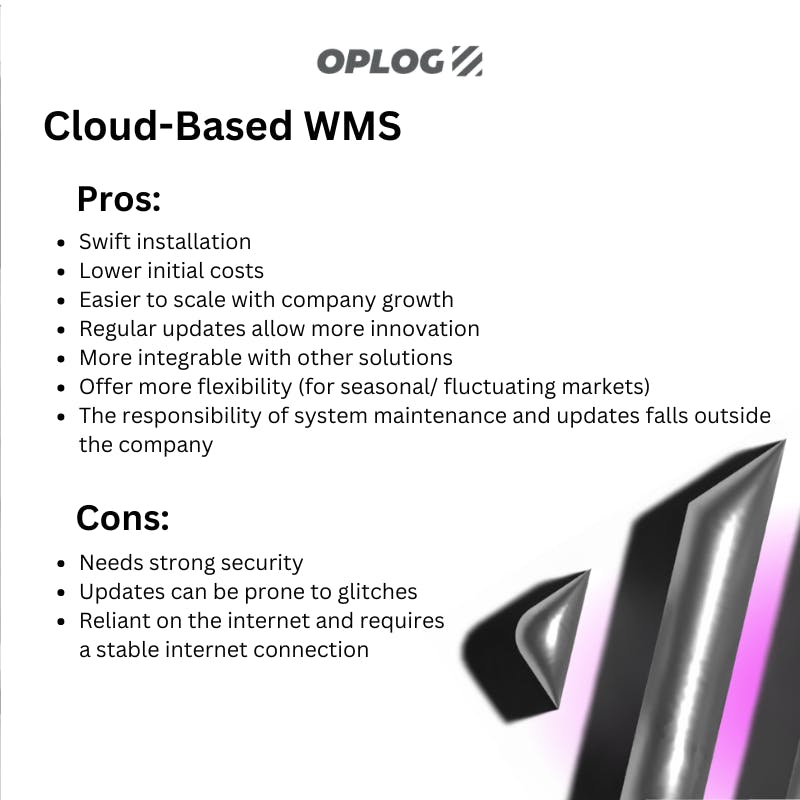

Choose Your Champion: Types of Warehouse Management Systems

Within the scope of warehouse management systems, there are three main categories. These include standalone, ERP-integrated, and cloud-based technologies. Depending on your needs, scale, and budget, a type may be more appealing to certain business models.

Standalone WMS

This type of system exists on the company property and utilizes its own hardware.

ERP-Integrated WMS

These systems are integrable applications for supply chain and ERP platforms.

Cloud-Based WMS

Cloud-based refers to a system hosted via the internet. They are delivered as software-as-a-service (SaaS).

Choose Wisely: Finding Your Perfect WMS Match

Selecting the right WMS isn't just about features—it's about finding a solution that grows with your business. Let's break down the selection process into manageable steps.

Know Your Warehouse Inside Out

Before diving into WMS options, take stock of your current operations:

- Map out your existing workflows

- Identify bottlenecks and pain points

- Document your inventory management processes

- Analyze your current technology stack

OPLOG's experience shows that understanding your current operations is crucial for selecting a system that truly addresses your needs rather than creating new challenges.

Define Your Must-Haves

Create a clear list of requirements based on:

- Current operational needs

- Growth projections

- Industry-specific requirements

- Integration necessities

- Budget constraints

Consider both immediate needs and future scalability—your WMS should grow alongside your business.

Set Clear Goals

Establish specific, measurable objectives for your WMS implementation:

- Target inventory accuracy rates

- Expected processing time improvements

- Desired customer satisfaction levels

- ROI expectations

- Specific efficiency metrics

Integration Capabilities

Ensure your chosen WMS plays well with:

- Your current e-commerce platforms

- ERP systems

- Shipping and carrier services

- Accounting software

- Customer service tools

Look for solutions that offer seamless integration with hundreds of marketplaces and platforms via Open API.

Technical Requirements

Evaluate the technical aspects:

- Hardware compatibility

- Network requirements

- Security protocols

- Backup systems

- Mobile accessibility

Budget Considerations

Factor in all potential costs:

- Initial software investment

- Implementation expenses

- Training requirements

- Ongoing maintenance

- Potential upgrade costs

Consider flexible options like OPLOG's "pay-as-you-go" model, which eliminates fixed costs and hidden fees. This is called "no-contract fulfillment", distinguishing fulfillment providers adopting this payment method from others.

Vendor Evaluation

Investigate available solutions and companies while choosing your WMS. When researching WMS providers:

- Check their industry experience

- Review client testimonials

- Evaluate support services

- Assess their financial stability

- Consider their innovation track record

Conduct A Needs Analysis

This measures the space for improvement between existing operations and targets. Lay out workflow maps to see what data is needed, where, for each step of decisions. Again, gather team input from those who will work in close contact with your system.

Plan For Implementation and Training

After all other assessments are complete, create a WMS roll-out timeline. This will need stages for testing, feedback, and staff training. Teams need to feel happy with their software understanding, while data needs prepping for data migration.

Future-Forward: WMS and Emerging Technologies

The warehouse of tomorrow is already here, with cutting-edge technologies transforming how WMS operates. Let's explore how these innovations are reshaping the fulfillment landscape:

AI and Automation: Your Warehouse's New Best Friends

Artificial Intelligence isn't just a buzzword—it's revolutionizing warehouse management. Through machine learning algorithms, modern WMS solutions like OPLOG's can:

- Predict inventory needs before stockouts occur

- Optimize picking routes in real-time

- Automate decision-making processes

- Enhance accuracy in order fulfillment

Speaking of automation, OPLOG's award-winning robot TARQAN showcases how robotics can transform warehouse operations, achieving 99.99% picking accuracy and 400% faster order fulfillment compared to manual processes.

IoT: Making Your Warehouse Smarter

The Internet of Things (IoT) turns your warehouse into a connected ecosystem where every asset communicates in real-time. Through sensor networks and smart devices, IoT integration enables:

- Real-time location tracking of inventory

- Automated temperature and condition monitoring

- Predictive maintenance for warehouse equipment

- Enhanced security and access control

Implementation: Making Your WMS Work for You

When it comes to finally introducing a WMS into your warehousing set-up, there are a few key points to keep in mind. It is vital to have a sound plan to ensure a smooth transition for effective implementation. When in doubt, voice all your concerns with your chosen WMS team to clarify and address action points.

Step 1: Design Your Success

Start with a system that fits your unique needs. Work closely with your WMS provider to customize:

- User interfaces that make sense for your team

- Workflows that match your operations

- Reporting tools that deliver actionable insights

- Integration points with existing systems

Step 2: Data Migration Magic

Ensure a smooth transition by:

- Cleaning and organizing your existing data

- Validating inventory information

- Setting up proper data hierarchies

- Testing data accuracy before going live

Step 3: Train and Test

Success depends on your team's comfort with the new system:

- Provide comprehensive training sessions

- Run real-world scenario testing

- Document processes and create quick reference guides

- Establish a support system for questions and troubleshooting

Step 4: Go-Live Preparation

Before launching:

- Verify all system settings

- Confirm user access levels

- Double-check integration points

- Prepare contingency plans

Step 5: Launch and Monitor

During and after go-live:

- Monitor system performance closely

- Address issues promptly

- Gather user feedback

- Make necessary adjustments

Step 6: Continuous Improvement

Keep your WMS operating at peak performance:

- Regular system audits

- Performance metric tracking

- User feedback collection

- Periodic training updates

Making the Move: Your Next Steps

Ready to transform your warehouse operations? Consider these action items:

- Assess your current warehouse pain points

- Define your must-have WMS features

- Research potential providers

- Request demos and consultations

- Plan your implementation timeline

Remember, a WMS isn't just software—it's an investment in your business's future. With the right system and partner, like OPLOG, you can achieve:

- Enhanced inventory accuracy

- Improved operational efficiency

- Better customer satisfaction

- Increased scalability

- Reduced operational costs

Whether you're handling a few dozen orders or thousands per day, a modern WMS can help you stay competitive in today's fast-paced e-commerce landscape. The future of warehousing is digital, automated, and intelligent—and it's time to be part of it.

Your WMS Questions Answered