In today's dynamic e-commerce landscape, choosing the right storage and shipping solution can make or break your business success. Whether you're managing an established enterprise or scaling your online store, understanding the distinct advantages of warehouses and fulfillment centres is crucial for optimizing your supply chain operations and maintaining customer satisfaction.

The Evolution of Modern Storage Solutions

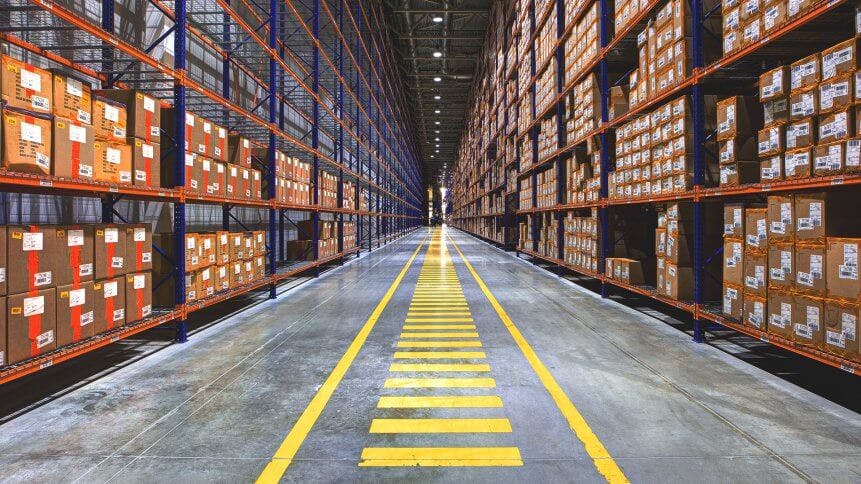

A warehouse is a large facility used to securely store goods and materials. It is designed for long-term storage and usually holds inventory in bulk. Warehouses are essential for maintaining a steady supply of products and managing stock levels.

According to the UKWA & Savills report 2024, the UK warehouse market has grown by 61% since 2015, approaching 700 million square feet of space. This remarkable expansion reflects the increasing sophistication of storage solutions and the growing demands of e-commerce businesses.

Understanding Warehouses: Your Long-term Storage Solution

A warehouse serves as a secure facility designed for storing goods and materials over extended periods. Let's explore the various types of warehouses that serve different business needs:

Public Warehouses

Public warehouses represent one of the most versatile storage solutions in today's market. These facilities, managed by experienced third-party logistics (3PL) providers, offer flexible solutions that adapt to your business needs. Before choosing a public warehouse, consider these key features:

- Scalable storage space that grows with your business

- Professional inventory management systems

- Cost-effective solutions for seasonal businesses

- Flexible rental terms without long-term commitments

Private Warehouses

Private warehouses offer businesses complete control over their storage operations. These company-owned facilities are typically customized to meet specific operational requirements, featuring advanced inventory management systems that integrate seamlessly with existing business processes. Companies operating private warehouses benefit from enhanced security measures and the ability to modify storage conditions according to their unique needs. This level of control makes private warehouses particularly valuable for businesses with consistent, high-volume storage requirements or those handling sensitive materials requiring specialized care.

Bonded Warehouses

Bonded warehouses play a crucial role in international trade, serving as secure storage facilities for imported goods before customs duties are paid. Operating under strict customs authority supervision, these specialized warehouses enable businesses to defer duty payments until products are ready for distribution. This arrangement proves particularly beneficial for companies involved in international trade, as it helps manage cash flow while ensuring complete compliance with import regulations. The security and regulatory oversight provided by bonded warehouses make them indispensable for businesses with significant import operations.

Climate-controlled Warehouses

Climate-controlled warehouses represent the pinnacle of specialized storage solutions, maintaining precise environmental conditions crucial for sensitive products. These facilities employ sophisticated temperature and humidity control systems to protect everything from perishable foods to pharmaceutical products and delicate electronics. The controlled environment prevents product degradation, extends shelf life, and ensures that items remain in optimal condition throughout their storage period. This level of environmental control has become increasingly important as businesses expand their product ranges and face stricter quality control requirements.

Automated Warehouses

Automated warehouses utilize advanced technologies such as robotics, conveyor systems, and inventory management software. These systems streamline the storage and retrieval process, reducing human error and increasing efficiency. Automated warehouses are ideal for businesses looking to improve accuracy and speed in their e-commerce warehousing operations.

Distribution Centres

Distribution centres are specialized warehouses designed to receive, process, and ship products. Often confused with fulfillment centres, distribution centres focus on the bulk distribution of goods to retailers or other distribution points. Fulfillment centres are more customer-oriented, handling the entire order fulfillment process from picking to directly shipping orders to customers.

The Future of Fulfillment: More Than Just Storage

The modern fulfillment landscape has evolved far beyond the traditional "store and ship" model. Today's fulfillment centres operate as sophisticated hubs where artificial intelligence, robotics, and human expertise converge to create seamless e-commerce experiences. These technology-driven facilities don't just store your products—they actively participate in your business growth by optimizing every step from inventory management to last-mile delivery. As e-commerce continues to reshape consumer expectations around speed and accuracy, fulfillment centres have become the backbone of successful online retail operations.

What is a Fulfillment Centre?

A fulfillment centre is a large facility that handles the entire order fulfillment process. This includes storing inventory, receiving orders, picking and packing products, shipping, and handling returns. Fulfillment centres are designed to streamline the process of getting products to customers quickly and efficiently.

More on Fulfillment Centres: Your E-commerce Powerhouse

Fulfillment centres represent the evolution of storage and shipping solutions, offering comprehensive services that go beyond traditional warehousing. Before diving deeper into the key services of fulfillment centres, you can explore our comprehensive guide to e-commerce fulfillment centres to discover how modern fulfillment solutions can drive your business growth.

Advanced Order Processing

Modern fulfillment centres have revolutionized order processing through sophisticated technology integration. By leveraging AI-powered systems and automated workflows, these facilities significantly reduce processing times while improving accuracy. The implementation of smart picking systems, like OPLOG's TARQAN robot, has transformed traditional fulfillment operations into highly efficient, automated processes. Integrated shipping solutions ensure smooth transitions from processing to delivery, while real-time order tracking capabilities keep both businesses and customers informed throughout the fulfillment journey. Consider OPLOG’s increased visibility service via OPLOG ONE, showing the order fulfillment steps live:

Inventory Intelligence

The cornerstone of modern fulfillment centres lies in their sophisticated inventory management capabilities. These systems go beyond basic stock counting, employing predictive analytics to forecast demand and prevent stockouts. Through real-time monitoring, businesses can track stock levels with unprecedented accuracy, while automated reordering systems ensure optimal inventory levels. OPLOG's smart warehousing solutions incorporate FIFO methods for effective expiration date management, particularly crucial for businesses dealing with time-sensitive products. This intelligent approach to inventory management helps businesses maintain optimal stock levels while minimizing waste and maximizing efficiency.

Breaking Free from Fixed Fees: The Pay-As-You-Go Revolution

Traditional warehouses often tie businesses down with fixed storage fees and long-term contracts, creating financial pressure especially during slower seasons. OPLOG has revolutionized this model with our unique no-contract fulfillment service. Unlike conventional storage solutions, our pay-as-you-go pricing model eliminates financial risks while enabling true scalability. This means you only pay for the space and services you actually use, optimized through our sophisticated combination of skilled staff and advanced technology. With no minimum volume requirements or hidden costs, this flexible approach represents a significant shift from traditional warehousing models, offering businesses the freedom to scale their operations according to real-time needs.

Making the Right Choice: Factors to Consider

Choosing between a warehouse and a fulfillment centre represents a crucial business decision that impacts your operational efficiency and growth potential. Consider these key factors when making your choice:

When to Choose a Warehouse:

- Long-term storage requirements

- Bulk inventory management needs

- Predictable storage patterns

- Focus on B2B operations

- Seasonal inventory fluctuations

When to Choose a Fulfillment Centre:

- High-volume order processing

- Need for real-time inventory visibility

- Multiple shipping requirements

- Scalable operations demands

- Customer service priorities

The OPLOG Advantage: Technology Meets Efficiency

At OPLOG, we've developed a comprehensive suite of solutions that transform traditional fulfillment operations. Our technology-driven approach delivers measurable advantages:

- OPLOG ONE: Complete management platform offering real-time visibility and control

- TARQAN: Revolutionary picking robot achieving 99.99% accuracy

- Smart WMS: AI-powered warehouse management system

- Omnichannel capabilities: Seamless integration of B2B and B2C operations

- No-contract fulfillment: Pay-as-you-go pricing model that offers flexibility and scalability

You’ve Got Questions? We’ve got Answers!